Get A Free Quote!

Why Do I Need My Kitchen Hood Cleaned?

If you own a bar, restaurant or any other business with a commercial kitchen in Wisconsin, you are required to have your hood cleaned on a regular basis. The purpose of your kitchen hood is to trap grease, smoke, and grime preventing pollutants to escape into the rest of your kitchen or restaurant. If not properly cleaned and maintained, the grease buildup poses a serious risk of fire. In addition to fire hazards, there are numerous other reasons to keep your kitchen exhaust system clean.

If you own a bar, restaurant or any other business with a commercial kitchen in Wisconsin, you are required to have your hood cleaned on a regular basis. The purpose of your kitchen hood is to trap grease, smoke, and grime preventing pollutants to escape into the rest of your kitchen or restaurant. If not properly cleaned and maintained, the grease buildup poses a serious risk of fire. In addition to fire hazards, there are numerous other reasons to keep your kitchen exhaust system clean.

Top Reasons For Routine Exhaust Hood Cleaning

Reduced Fire Hazards

Over time, grease, oil and other grime collects in your kitchen hood creating a sticky and extremely flammable substance that can easily be ignited. This puts your employees, customers, assets, and building in danger of a fire emergency. Regular cleaning from Affordable Hood Cleaning is the easiest way to prevent these devastating fires.

Improved Air Flow and Quality

Regular cleaning of your kitchen hood and filters prevents the build up of grease on exhaust fans. When the exhaust fans are clean, more air is able to be exhausted. Not only will this extend the life of your fan, but better air flow means reduced odors and smoke from grease and oil, cooler work environment and proper airflow in your kitchen.

Compliance with Local and National Codes

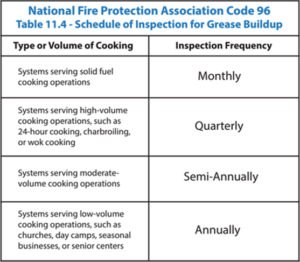

Fire codes, local fire officials and insurance carriers all require kitchen hoods and exhaust to be kept clean and well maintained at all times. If a fire official would come for an inspection today and finds a dirty, greasy hood, you could end up with a hefty fine or even risk having your business shut down. Violation of codes could also result in your insurance carrier dropping coverage or increasing your premium. Insurance companies use the NFPA 96 guidelines to determine who is at fault for a fire. Don't let it be yours! Schedule an exhaust hood cleaning service from Affordable Hood Cleaning.

Give us a call today at (414) 405-8500 and book an appointment today with one of our expert kitchen exhaust cleaners.

NFPA 96 STANDARDS

7.8.2.1 (4) The ability to drain grease out of any traps or low points formed in the fan or duct near the termination of the system into a collection container that is noncombustible, closed, rainproof, and structurally sound for the service to which it is applied and that will not sustain combustion.

7.8.2.1 (4) The ability to drain grease out of any traps or low points formed in the fan or duct near the termination of the system into a collection container that is noncombustible, closed, rainproof, and structurally sound for the service to which it is applied and that will not sustain combustion.

11.6.2* Hoods, grease removal devices, fans, ducts, and other appurtenances shall be cleaned to remove combustible contaminants prior to surfaces becoming heavily contaminated with grease or oily sludge.

8-3.1.1 Upon inspection, if found to be contaminated with deposits from grease-laden vapors, the entire exhaust system shall be cleaned by a properly trained, qualified, and certified company or person(s) acceptable to the authority having jurisdiction in accordance with Section 8-3.

3-2.3 Grease filters shall be listed and constructed of steel or listed equivalent material and shall be of rigid construction that will not distort or crush under normal operation, handling, and cleaning conditions. Filters shall be tightfitting and firmly held in place.

4-3.1 Openings shall be provided at the sides or at the top of the duct, whichever is more accessible, and at changes of direction. Openings shall be protected by approved access panels that comply with 4-3.4.4. Exception: Openings shall not be required in portions of the duct that are accessible from the duct entry or discharge.

5-1.1 Approved upblast fans with motors surrounded by the airstream shall be hinged, supplied with flexible weatherproof electrical cable and service hold-open retainers, and listed for this use.

6.2.3.1 Grease filters shall be listed and constructed of steel or listed equivalent material

6.2.3.2 Grease filters shall be rigid construction that will not distort or crush under normal operation, handling, and cleaning conditions.

6.2.3.3 Grease filters shall be arranged so that all exhaust air passes through the grease filters.

7.3.1 Openings shall be provided at the sides or at the top of the duct, whichever is more accessible, and at changes of direction.

7.4.1.3 Openings on horizontal grease duct systems shall be provided with safe access and a work platform when not easily accessible from a 3 m (10 ft) stepladder.

8.1.1.1 Approved upblast fans with motors surrounded by the airstream shall be hinged, supplied with flexible weatherproof electrical cable and service hold-open retainers, and listed for this use.

8.1.5.3.1 Upblast fans shall be supplied with an access opening of a minimum 76 mm by 127 mm (3 in. by 5 in.) or a circular diameter of 101 mm (4 in.) on the curvature of the outer fan housing to allow for cleaning and inspection of the fan blades.

11.6.10 When an access panel is removed, a service company label or tag preprinted with the name of the company and giving the date of inspection or cleaning shall be affixed near the affected access panels.

* Reprinted with permission from NFPA 96 Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations ©1998, National Fire Protection Association, Quincy, MA 02269. The reprinted material is not the complete and official position of the National Fire Protection Association, on the referenced subject, which is represented only by the standard in its entirety.</div>